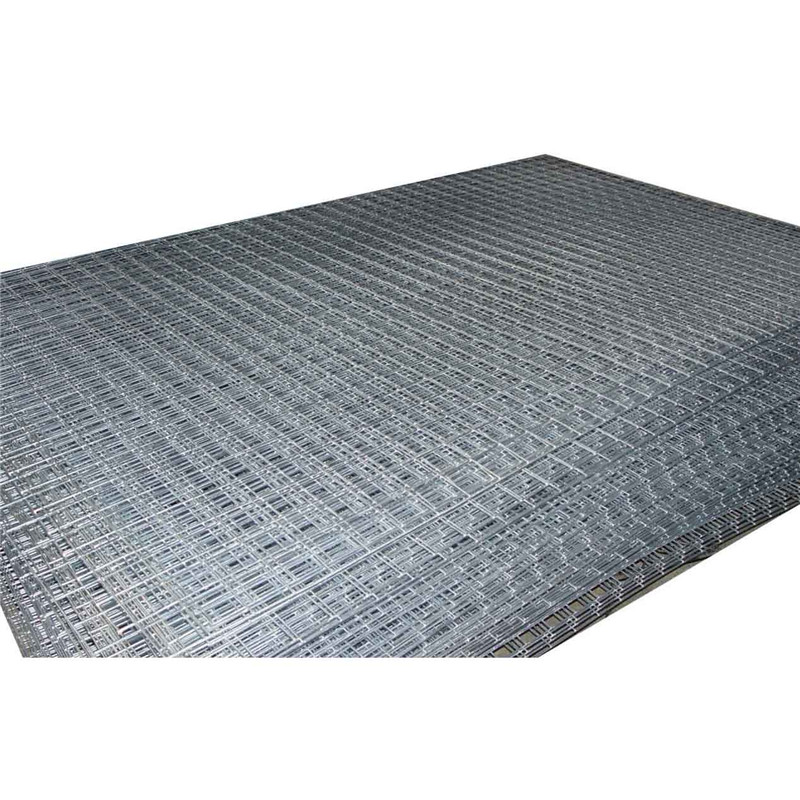

WELDED WIRE MESH (Used in application of ground support)

WELDED WIRE MESH FEATURES

● Welded Wire Mesh was made by black or galvanized wire

● Different grade of wire available to meet customer special required

● Different size of mesh available

● Different diameter of wire rod available

● Mesh fabrication can be made to meet different requirements

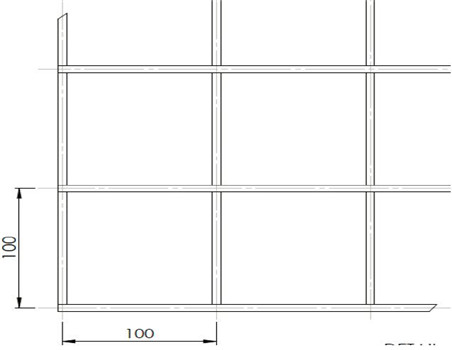

WELDED WIRE MESH SPECIFICATION

| SPEC. | WIRE TYPE | WIRE DIA | WIRE SPACING | NO. OFF | LENGTH | FINISH | ||||||

| SIZE (mm) | mm | mm | PCS | mm | ||||||||

| 3000×1700 | Long Wire | 5.6 | 100 | 18 | 3006 | Gal. Wire | ||||||

| Cross Wire | 5.6 | 100 | 31 | 2406 | Gal. Wire | |||||||

| 3000×2400 | Long Wire | 5.6 | 100 | 25 | 3006 | Gal. Wire | ||||||

| Cross Wire | 5.6 | 100 | 31 | 2406 | Gal. Wire | |||||||

| 3000×2400 | Long Wire | 5.0 | 100 | 25 | 3005 | Gal. Wire | ||||||

| Cross Wire | 5.0 | 100 | 31 | 2405 | Gal. Wire | |||||||

| 3000×2400 | Long Wire | 4.95 | 100 | 25 | 3005 | Gal. Wire | ||||||

| Cross Wire | 4.95 | 100 | 31 | 2405 | Gal. Wire | |||||||

Note: Wire spacing can be made with 25×25, 50×50, 50×75, 75×75, special requirements can be negociated

WELDED WIRE MESH CHARACTERS

● Min. Tensile Strength of Wire: 400Mpa

● Max. Tensile Strength of Wire: 600Mpa

● Min. Weld Shear: 9.3KN

● Min. Torque Value: 18Nm

● Min. welding Penetration: 10%

● Typically average Zinc Coating: 100g-275g/m²

As the main coverage and protection material, mesh is widely used in ground support projects. With advantage automatic mesh welding facility, TRM can supply hundred and hundred tons of welding mesh in a very short period of time. Our mesh facility is very efficient which could feeding the long and cross wires automatically and press welding the whole sheet of mesh by one time, that make us getting a very low labour cost and could supply mesh with very low prices. Meanwhile, TRM quality control system can control the quality of each processes very well and a tracking records will go through the whole production from raw material to the final packed mesh, which could make sure all the mesh with perfect performance. We also could make the pull test for the welds as customer’s requirements, and a pull test report will be issued together with each batch of new Mesh.